From 100kg to 1500kg

Scaling Vibration Solutions for Enterprise Growth

Enterprise growth in precision manufacturing demands infrastructure that can scale without complete system overhauls. Modern modular vibration isolation systems offer unprecedented flexibility, supporting loads from 100kg to 1500kg per module while maintaining consistent performance standards. This scalability represents a strategic advantage for companies planning long-term expansion in high-precision industries.

The Scalability Challenge in Precision Manufacturing

Traditional Infrastructure Limitations

Most manufacturing facilities face a critical dilemma during expansion: existing vibration isolation systems become obsolete as production requirements evolve. Legacy passive systems typically support fixed load ranges, forcing companies to:

- Replace entire isolation systems during facility upgrades

- Accept suboptimal performance for new equipment configurations

- Delay expansion projects due to infrastructure constraints

- Compromise on equipment placement based on existing system limitations

The Hidden Costs of Non-Scalable Solutions

When vibration isolation systems cannot accommodate growth, enterprises encounter significant financial and operational penalties:

Infrastructure Replacement Costs:

- Complete system redesign and installation

- Production downtime during transitions

- Equipment, recertification and validation

- Staff retraining on new systems

Operational Limitations:

- Restricted equipment placement options

- Suboptimal facility layout efficiency

- Reduced manufacturing flexibility

- Compromised future expansion capabilities

Modular Design: The Foundation of Scalable Solutions

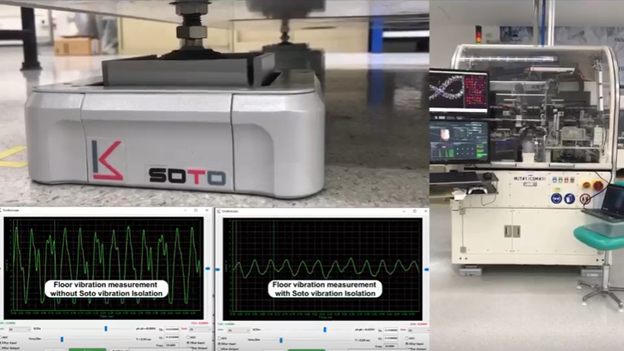

ARIS MD Pro Modular Architecture

The ARIS MD Pro system addresses scalability through its modular design philosophy, offering:

Load Capacity Range: 100-1500 kg per isolator module

Frequency Coverage: 0.5-100 Hz across all configurations

Response Time: < 0.1 seconds regardless of load

Operating Range: 0°C to 50°C for all modules

Technical Scalability Advantages:

1. Flexible Load Distribution Each module independently supports 100-1500 kg, allowing for:

- Asymmetric load configurations

- Progressive capacity increases

- Equipment-specific optimization

- Future-proof installation planning

2. Consistent Performance Standards Unlike passive systems where performance degrades with scaling, active modules maintain:

- Identical frequency response across all load ranges

- Uniform response times regardless of configuration

- Consistent isolation effectiveness

- Standardized control parameters

3. Modular Expansion Capability The system design enables:

- Addition of modules without system reconfiguration

- Integration with existing installations

- Incremental capacity increases

- Cost-effective expansion pathways

Strategic Applications Across Growth Phases

Startup Phase: 100-500kg Applications

Initial Investment Optimization: Small-scale precision manufacturing operations benefit from entry-level configurations:

- Tabletop Microscopy: Individual modules supporting laboratory-scale equipment

- R&D Instrumentation: Flexible configurations for research applications

- Prototype Manufacturing: Adaptable setups for changing equipment requirements

Growth Preparation: Even in startup phases, modular systems provide:

- Expansion pathways without infrastructure replacement

- Consistent performance standards as operations scale

- Investment protection through system longevity

Scale-Up Phase: 500-1000kg Applications

Production Equipment Integration: Mid-range configurations support expanding manufacturing operations:

- Semiconductor Process Tools: Multi-module configurations for production equipment

- Medical Device Manufacturing: Scalable platforms for assembly operations

- Precision Machining Centers: Flexible support for varying equipment weights

Operational Efficiency: Modular systems during scale-up provide:

- Rapid reconfiguration capabilities

- Minimal disruption during expansion

- Standardized maintenance procedures

- Simplified staff training requirements

Enterprise Phase: 1000-1500kg Applications

Heavy Equipment Support: Full-scale manufacturing operations require maximum capacity configurations:

- Advanced Lithography Systems: Multi-module arrays supporting critical semiconductor tools

- Large-Scale Metrology Equipment: High-capacity platforms for inspection systems

- Automated Manufacturing Lines: Comprehensive isolation for integrated production systems

Strategic Advantages: Enterprise-level implementations offer:

- Complete facility optimization

- Maximum equipment placement flexibility

- Future-proof infrastructure investment

- Competitive manufacturing capabilities

Economic Analysis of Scalable Solutions

Investment Efficiency Over Time

Traditional Approach Costs:

- Initial system: $X

- First expansion: Replace entire system ($X + installation costs)

- Second expansion: Replace the entire system again ($X + installation costs)

- Total investment over 10 years: 3X + significant installation and downtime costs

Modular Approach Benefits:

- Initial system: $Y (comparable to traditional)

- First expansion: Add modules ($0.3Y, no replacement needed)

- Second expansion: Add modules ($0.3Y, no replacement needed)

- Total investment over 10 years: 1.6Y + minimal installation costs

Return on Investment Calculations

Scalability Premium Recovery: The modular approach typically recovers its premium through:

- Reduced replacement costs: 60-70% savings on expansion projects

- Minimized downtime: 80-90% reduction in production interruptions

- Enhanced flexibility: 40-50% improvement in equipment placement options

- Future-proofing value: Protection against obsolescence costs

Total Cost of Ownership Advantages

Operational Savings:

- Maintenance standardization: Single system type across all configurations

- Staff efficiency: Unified training and operational procedures

- Inventory optimization: Common spare parts across all modules

- Service efficiency: Standardized service protocols and schedules

Technical Implementation Strategies

Capacity Planning Best Practices

Load Distribution Analysis: Effective modular implementation requires:

- Detailed current equipment weight analysis

- Projected future equipment requirements

- Load distribution optimization studies

- Growth scenario planning

Configuration Optimization: Strategic module placement considers:

- Current and future equipment layouts

- Facility infrastructure constraints

- Maintenance access requirements

- Expansion pathway preservation

Integration with Existing Infrastructure

Retrofit Considerations: Modular systems excel in retrofit applications through:

- Minimal structural modification requirements

- Phased implementation capabilities

- Compatibility with existing facility systems

- Reduced installation complexity

New Facility Design: Purpose-built facilities benefit from:

- Optimized foundation design for modular systems

- Pre-planned expansion zones

- Integrated utility routing

- Future-ready infrastructure

Performance Consistency Across Scale

Vibration Isolation Effectiveness

Frequency Response Uniformity: Unlike passive systems where performance varies with load, modular active systems maintain:

- Consistent 0.5-100 Hz coverage regardless of configuration

- Uniform transmissibility characteristics across all load ranges

- Identical response times independent of module count

- Standardized performance metrics for all configurations

Quality Assurance Benefits

Manufacturing Consistency: Uniform performance across all production equipment ensures:

- Consistent product quality regardless of equipment size

- Standardized process validation procedures

- Simplified quality control protocols

- Reduced process variation

Risk Management Through Scalability

Technology Obsolescence Protection

Future-Proof Investment: Modular systems protect against:

- Technology evolution: Upgradeable components without system replacement

- Capacity changes: Scalable to accommodate future requirements

- Performance standards: Adaptable to evolving industry requirements

- Regulatory compliance: Flexible to meet changing standards

Operational Risk Mitigation

Business Continuity: Scalable systems reduce risks through:

- Gradual transition capabilities: No need for complete system shutdowns

- Redundancy options: Multiple modules provide backup capabilities

- Maintenance flexibility: Individual module service without system shutdown

- Rapid reconfiguration: Quick adaptation to changing requirements

Industry-Specific Scalability Applications

Semiconductor Manufacturing Growth

Fab Expansion Scenarios:

- Initial installation: Single process tool support (500-800 kg)

- Line expansion: Multiple tool configurations (1000-1200 kg)

- Facility scaling: Full production line support (1500 kg per module)

Strategic advantages:

- Consistent process conditions across all equipment

- Simplified validation procedures for new installations

- Reduced time-to-production for expansion projects

Medical Device Manufacturing Evolution

Production Scaling:

- Research phase: Laboratory equipment support (100-300 kg)

- Pilot production: Small-scale manufacturing equipment (400-700 kg)

- Commercial production: Full-scale manufacturing systems (800-1500 kg)

Regulatory benefits:

- Consistent validation protocols across all production phases

- Simplified regulatory submissions for scale-up

- Reduced qualification timelines for new equipment

Advanced Materials Research

Research Facility Growth:

- Basic research: Individual instrument support (200-400 kg)

- Applied research: Multi-instrument configurations (500-900 kg)

- Pilot development: Large-scale equipment support (1000-1500 kg)

Scientific advantages:

- Consistent experimental conditions across all research phases

- Simplified equipment comparison and validation

- Enhanced collaboration through standardized platforms

Implementation Roadmap for Scalable Solutions

Phase 1: Assessment and Planning

Current State Analysis:

- Existing equipment inventory and weights

- Current vibration isolation system evaluation

- Growth projection development

- Capacity requirement forecasting

Strategic Planning:

- Modular configuration design

- Expansion pathway definition

- Investment timeline development

- Risk assessment and mitigation planning

Phase 2: Initial Implementation

Pilot Installation:

- Critical equipment identification

- Initial module configuration

- Performance validation

- Staff training and certification

Performance Optimization:

- System calibration and tuning

- Performance monitoring establishment

- Maintenance protocol development

- Success metrics definition

Phase 3: Scaling and Expansion

Progressive Implementation:

- Additional module installation

- System integration and testing

- Performance consistency validation

- Operational procedure refinement

Continuous Optimization:

- Performance monitoring and analysis

- System optimization opportunities

- Future expansion planning

- Technology upgrade evaluation

Competitive Advantages of Scalable Vibration Isolation

Market Positioning Benefits

Operational Flexibility: Companies with scalable infrastructure gain:

- Faster response to market opportunities

- Reduced time-to-market for new products

- Enhanced customer service capabilities

- Improved competitive positioning

Technology Leadership

Innovation Enablement: Scalable systems support:

- Advanced manufacturing process adoption

- Next-generation equipment integration

- Research and development acceleration

- Technology partnership opportunities

Cost-Benefit Analysis Framework

Financial Modeling Considerations

Investment Evaluation Metrics:

- Initial capital requirements vs. traditional systems

- Expansion cost comparisons over 5-10 year periods

- Operational efficiency improvements and quantification

- Risk mitigation value assessment

Long-term Value Creation:

- Asset utilization optimization through flexible configurations

- Capacity expansion ROI acceleration

- Technology evolution protection value

- Competitive advantage monetization

Future-Proofing Through Modular Design

Emerging Technology Compatibility

Next-Generation Requirements: Modular systems prepare facilities for:

- Quantum computing applications requiring extreme stability

- Nanotechnology manufacturing with atomic-level precision

- Advanced AI and robotics integration

- Sustainable manufacturing process evolution

Regulatory Compliance Evolution

Standards Adaptation: Flexible systems accommodate:

- Evolving safety standards and requirements

- Environmental regulations and compliance

- Quality system updates and improvements

- Industry-specific certifications and validations

The transition from fixed-capacity to modular vibration isolation systems represents more than a technical upgrade—it's a strategic business decision that enables sustainable growth and competitive advantage.

Key Strategic Benefits:

- Investment Protection: Modular systems eliminate the need for complete replacement during expansion, protecting initial investments while enabling growth

- Operational Excellence: Consistent performance standards across all configurations ensure quality and efficiency regardless of scale

- Competitive Advantage: Rapid expansion capabilities and flexible configurations provide market responsiveness that fixed systems cannot match

- Future Readiness: Scalable infrastructure accommodates emerging technologies and evolving requirements without system obsolescence

The Scalability Imperative:

In today's rapidly evolving precision manufacturing landscape, the ability to scale efficiently determines long-term success. Companies that invest in modular, scalable vibration isolation systems position themselves for:

- Sustainable growth without infrastructure limitations

- Technology leadership through advanced manufacturing capabilities

- Market responsiveness via rapid expansion capabilities

- Competitive differentiation through operational excellence

The question for enterprise leaders isn't whether to invest in scalable solutions, but whether they can afford to limit their growth potential with fixed-capacity systems.

The modular approach to vibration isolation represents a paradigm shift from reactive infrastructure management to proactive growth enablement. Companies that embrace this approach today will lead their industries tomorrow.

Ready to evaluate your facility's scalability requirements? Contact precision manufacturing experts who can assess your current infrastructure and design modular solutions for sustainable growth.