The Equipment You Need Is Quietly Killing Your Yield

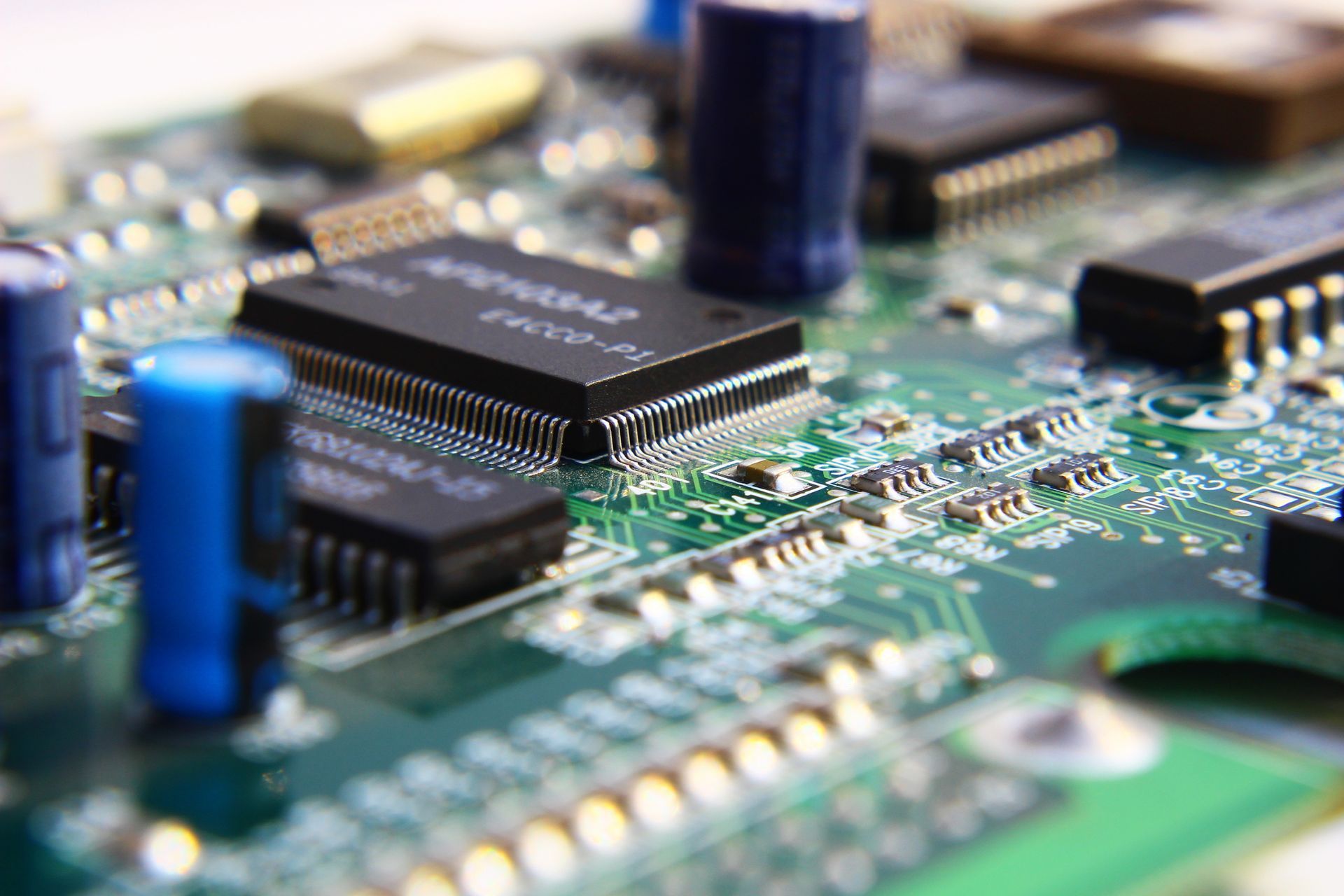

In semiconductor manufacturing, nanometer-level precision isn't a luxury—it’s the standard. Yet the very tools required to keep fabs running—process tools, pumps, and chillers—also generate mechanical vibrations that silently undermine production quality. These vibrations propagate through the fab floor, destabilize critical processes, and ultimately reduce yield.

This hidden challenge can have a profound impact on operational performance, profitability, and tool longevity. And it often goes unnoticed—until it's too late.

Internal Vibrations: The Hidden Noise in Your Fab

Within every advanced fab, a wide range of systems—vacuum pumps, cooling systems, air handling units, compressors, and rotating machinery—are indispensable. However, these same systems are notorious for generating low-frequency vibrational energy that can travel far beyond their immediate location.

While external vibrations (such as traffic or seismic events) are relatively rare, internal sources are persistent and pervasive. Studies show that unbalanced rotating components—such as fans, chillers, or HVAC dampers—introduce vibrations that can travel dozens or even hundreds of meters through pipelines, ductwork, or the subfloor of the fab.

These mechanical disturbances often turn the fab floor itself into a secondary vibration source, degrading the stability of precision equipment like lithography systems, metrology tools, and etchers.

How Vibrations Impact Semiconductor Yield

Yield loss due to vibration is both real and measurable. In photolithography, even minute misalignments caused by vibration can lead to pattern deformation, overlay errors, and critical dimension variations. In etch and deposition, these mechanical inputs translate into defects, blurred features, or non-uniformity across the wafer.

One analysis showed fabs without effective vibration isolation had yield rates dropping below 65%. In contrast, fabs that implemented source-level vibration mitigation systems regularly reported yields above 95%.

The math is simple:

- Higher vibration = lower accuracy

- Lower accuracy = lower yield

- Lower yield = less revenue, more scrap, higher costs

In a market where every nanometer counts, vibration isn't just a mechanical issue—it’s a business risk.

Fab Floor: From Passive Structure to Active Problem

Modern fabs often feature waffle slab floors or raised cleanroom structures designed to minimize vibration transmission. But no design can fully eliminate the propagation of mechanical energy from one system to another.

In one documented case, a 16 Hz harmonic vibration originated from an HVAC damper located over 120 meters away and traveled undetected through ductwork to sensitive lithography equipment—causing instability that required downtime and recalibration.

This example highlights the core issue: If you don't neutralize the source of vibration, your fab becomes the amplifier.

The Real Solution: Stop Vibration at the Source

Most fabs focus their vibration mitigation strategy on protecting sensitive tools—installing active or passive isolation platforms underneath expensive equipment. But this is only half the solution.

The more effective approach? Isolate the disruptors themselves.

Just as noise-cancelling headphones use inverse waveforms to neutralize sound at the source, K&S systems stop mechanical vibration at its origin. By applying tailored source-level vibration isolation solutions to pumps, chillers, and other high-vibration assets, fabs can reduce system-wide noise levels, improve operational stability, and extend the service life of their most sensitive instruments.

This proactive strategy translates directly into:

✔ Higher throughput

✔ Increased first-pass yield

✔ Reduced downtime

✔ Lower maintenance costs

✔ Better return on tool investment

Why Choose K&S Advanced Systems ?

At K&S Advanced Systems, we specialize in high-performance vibration isolation technologies engineered for nanometer-critical environments. Whether you’re dealing with a legacy fab layout or designing a new cleanroom from scratch, our solutions:

- Target the actual vibration sources (not just the symptoms)

- Integrate with your current infrastructure without major downtime

- Deliver quantifiable improvements in yield and stability

From active damping systems to custom passive isolation frameworks, our engineers deliver the kind of precision your yield depends on.

📩

Contact us today – and find out how K&S Advanced Systems can protect your fab from itself