Innovation Reduces Precision

When Innovation Reduces Precision: How Upgrade Strategies Can Quietly Harm Your Semiconductor Fab

In the semiconductor industry, precision is not a goal—it’s a baseline. As fabs race to adopt cutting-edge lithography, metrology, bonding, and inspection systems, there’s one critical question that often gets ignored:

Can your infrastructure support the precision your new tools demand?

More often than not, the answer is no.

Legacy Floors. Next-Gen Tools. One Hidden Conflict.

Modern bonding machines—wire, die, flip-chip—are essential for advanced packaging. But they also generate mechanical vibrations that propagate through fab floors, interfering with:

- Lithography

- Metrology systems

- Optical inspection tools

- Cleanroom calibration

The result?

❌ Drift in calibration

❌ Instability during processes

❌ Rising error rates and falling

yield

In older fabs, these issues are even more pronounced: floor vibration often exceeds VC-B standards, making reliable operation of sensitive tools nearly impossible.

Most Teams Make This Mistake: Treating the Symptoms, Not the Cause

A common approach is to install isolation platforms

under sensitive tools.

But if you don’t isolate

the source—pumps, chillers, HVAC systems, and bonding machines—you're just patching over a deeper problem.

The correct strategy is

source-level vibration isolation.

Think of it like active noise-cancelling headphones—not just blocking noise, but

inverting it at the source.

At K&S, that’s exactly what we do.

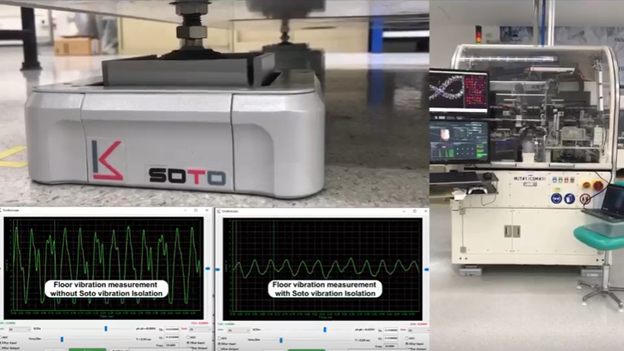

Case Study: Bonding Machines & the K&S Solution

Bonding equipment is a major vibration generator in packaging fabs.

K&S is the

only company worldwide that has successfully solved this in legacy fabs, using a proprietary combination of:

🎯 ArisMD PRO + FF System – an advanced active vibration control setup proven to:

- Reduce fab floor vibration by an order of magnitude

- Meet or exceed VC-C standards

- Enable modern packaging in old fabs without rebuilding the infrastructure

Predict Before You Lose: How Machine Learning Adds a New Layer

We’re entering a new era where vibration is not just controlled—it’s predicted.

K&S integrates machine learning models into its platform to:

- 📊 Predict yield degradation based on vibration trends

- 🔍 Correlate vibration peaks with process anomalies

- 🧠 Optimize tool layout during fab planning

Imagine a system that doesn’t just react—but alerts you to risk before the damage happens.

Predictive analytics is the future of fab management, and at K&S, we’re already there.

What’s Your Next Step?

✅ Planning a tool upgrade? Start with a vibration audit

✅ Experiencing process drift? Let’s look beneath your floor

✅ Want AI-based prediction? We’ll help you implement it

📩 Contact the K&S advanced systems LTD. team today—and let’s build real precision into your fab.

Even if it was built 20 years ago.