What If Vibration Control Holds the Key to IVF Success?

In the intricate world of in vitro fertilization (IVF), success often hinges on an array of interconnected factors: expert clinicians, advanced technologies, and optimal lab conditions. But what if there’s an unassuming element influencing outcomes that’s been largely overlooked? What if vibration control, and even its purposeful manipulation, holds untapped potential for transforming the IVF process?

The Quiet Influencer: Vibrations in IVF Labs

Vibrations are often seen as mere disturbances to be minimized. From the faint tremors caused by footsteps to the hum of lab equipment or even the rumble of nearby traffic, these vibrations disrupt the high-precision environment required for embryonic development. For decades, IVF labs have relied on passive anti-vibration systems to reduce these disturbances, aiming to ensure stable conditions for processes like ICSI (intracytoplasmic sperm injection) and embryo cultivation.

But what if we could move beyond simply isolating vibrations? Could controlled, purposeful vibrations mimic natural conditions found in the human body, offering benefits that static systems cannot?

What Science Suggests

A groundbreaking study published in Reproductive BioMedicine Online explored the impact of controlled micro-vibrations on human embryos during in vitro culture. The findings were intriguing: embryos exposed to subtle, rhythmic mechanical vibrations demonstrated higher implantation rates compared to those in static environments. The researchers hypothesized that these vibrations could replicate the natural mechanical stimuli embryos experience as they travel through the fallopian tubes, thereby promoting healthier development.

This study raises an intriguing question for IVF labs: are we missing an opportunity to enhance outcomes by integrating purposeful vibration systems alongside traditional isolation technologies?

Rethinking Vibration Control in IVF

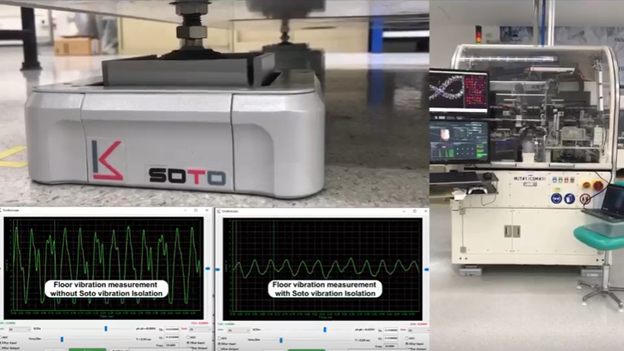

At K&S Advanced Systems Ltd., we specialize in advanced vibration isolation solutions designed to create stable environments for sensitive equipment. Our systems are engineered to eliminate unwanted vibrations, ensuring the precision needed for IVF procedures. However, as the field evolves, we find ourselves asking: could the future of IVF involve a dual approach—isolating harmful vibrations while leveraging controlled ones to mimic natural conditions?

Imagine an IVF lab equipped with a hybrid system. Harmful external vibrations are neutralized by advanced isolation technologies, while carefully calibrated micro-vibrations are introduced at specific stages of embryo cultivation to stimulate natural developmental processes. Such a system could represent the next frontier in reproductive medicine, bridging the gap between laboratory precision and biological authenticity.

What If You Could Transform Your Lab?

While the idea of integrating controlled vibrations into IVF processes remains in the exploratory stage, the potential benefits are compelling. Could such innovations:

Increase embryo implantation rates?

Improve the overall quality of embryos?

Reduce the time and resources required for successful fertilization?

These are questions worth exploring—and at K&S, we are eager to collaborate with IVF professionals who are ready to push the boundaries of what’s possible in reproductive medicine.

Let’s Explore the Future Together

If the idea of transforming your IVF lab with cutting-edge vibration control technologies intrigues you, we invite you to connect with us. At K&S Advanced Systems Ltd., we don’t just provide solutions; we partner with you to pioneer advancements in precision and performance.

Reach out today to learn how our systems can help your lab achieve the stability and innovation required for success in IVF.

*** At this time, there are no published studies directly refuting the findings of “In-vitro culture of human embryos with mechanical micro-vibration increases implantation rates” (rbmojournal.com). However, it is worth noting that the effectiveness of micro-vibration in embryo cultivation requires further research and validation. For instance, the study “A Comparison of Embryonic Development and Clinical Outcomes between In vitro Oocytes Maturation Using Micro-Vibration System and In vivo Oocytes Maturation in Polycystic Ovarian Syndrome Patients” indicates that mechanical micro-vibration does not always improve the conditions for oocyte maturation (karger.com). Therefore, while no direct refutations exist, additional data is needed to draw definitive conclusions regarding the application of micro-vibration in assisted reproductive technologies.